Today, labs are under increasing pressure to generate reliable research results that can quickly be transformed into valuable products. The need for efficient operations and demand for high-throughput processes present significant challenges to meeting these goals.

Research laboratories often decide to incorporate automation due to limitations with manual workflows. Integrating automation into research can transform productivity, ensure maximum reproducibility, improve safety, and boost efficiency throughout the research pipeline. Here, we look at the benefits of laboratory automation and how they help scientists meet their research goals on time and within budget.

What is Laboratory Automation?

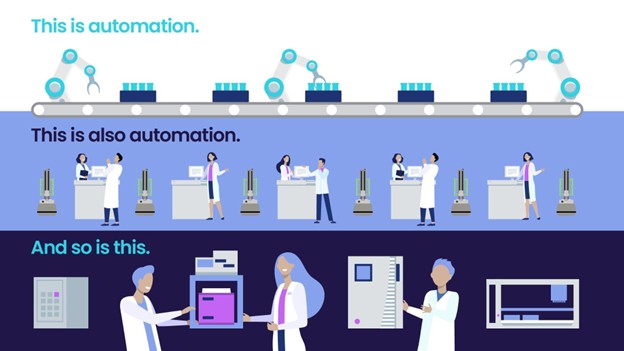

Laboratory automation means incorporating technologies into the research process that can take on the burden of the repetitive, high-precision tasks that can otherwise consume a large portion of a scientist’s day. With laboratory automation benefitting scientist’s schedules, they can focus on higher-level work, like designing experiments and interpreting results.

Automated solutions can facilitate each stage of the research workflow. The basic types of automation are:

- Pre-analytical: Before a sample is analyzed, automated processes can help ensure that samples are correctly labeled, sorted, and prepared for analysis.

- Analytical: Automated analysis involves machines and software that collect data with great speed, precision, and reliability.

- Post-analytical: Automated solutions can perform quality control, run additional tests if necessary, and archive and store samples.

Automation is not all-or-nothing. Many labs employ stand-alone automated solutions, like robotic liquid handlers, to help optimize the most labor-intensive portions of their workflow. On the other hand, some large laboratories orchestrate automation from start-to-finish in the research process, enabling total laboratory automation (TLA).

5 Laboratory Automation Benefits

1. Increased Staff Productivity

The most well-known benefits of laboratory automation are related to increased staff productivity. While lab demands are always increasing, automation allows a higher throughput of experiments each day without needing to hire more people. Because robots don’t get tired or need breaks, they can complete repetitive and tedious tasks that would take scientists much longer, making sure that key results arrive as quickly as possible.

Automation also extends a lab’s productive hours, allowing scientific processes to continue running into evenings, overnight, and even throughout weekends long after the scientist has left the laboratory. Automated solutions are highly scalable, allowing labs to ramp up their productivity as needed.

Here are a few ways that laboratory automation benefits productivity:

- Robots can grow cell lines under tightly controlled conditions and then perform assays at scheduled points in development, no matter the time of day.

- Automation allows high-throughput screening of drug candidates, greatly accelerating the process of identifying effective molecules.

- An automated solution for protein purification reduced the process run-time by half.

2. Enhanced Research Quality and Data Integrity

Typical lab operations might involve running assays with sub-microliter fluid volumes. However, manually inputting the same minuscule volume across many samples is challenging, and human error can influence results. With automation, scientists can run these experiments at scale with consistent inputs. As a result, test results are more accurate, and experimental results are more reproducible.

In a clinical context, using automation to handle and test samples can improve testing consistency and minimize human errors that can occur during sample labeling and data entry.

3. Improved Workflow Management

Automation plans that keep track of every step in a lab’s daily workflow result in more predictable throughput and outcomes, yielding laboratory efficiency improvements through data-backed decision-making. Scientists can be confident that their experimental processes are thoroughly documented and their samples tracked. Lab employees are likely to be less stressed when they know that details necessary for experimental reproducibility and compliance are unlikely to contain human errors in documentation.

Automated workflow management is also important for experiments with more specialized requirements. For example, in experiments that use temperature-sensitive reagents, robots can be programmed to dispense these reagents into assay plates at the appropriate time and temperature, even if the scientists are not there.

4. Safer Working Conditions

Some lab processes are hazardous, involving exposure to harmful chemicals or pathogens. Automating these processes creates a safer work environment. Robots can also handle experiments that involve a lot of repetitive motion, which can take a toll on workers’ physical and mental health. For example, liquid-handling robots can take over much of the pipetting, contributing to repetitive strain injuries in scientists. Beyond physical safety, automation can improve morale, freeing employees from tedious or potentially hazardous tasks and allowing them to focus on more engaging aspects of their work.

While there can be concerns about automation changing team dynamics, we see robots as tools that empower lab personnel. Automation not only makes certain types of research possible through increased speed and precision but also enhances the overall workflow, letting people focus on the creative challenges in their next discovery.

5. Cost Savings and Return on Investment

Automated solutions can quickly pay for themselves by improving experimental outputs while reducing operating and labor costs. This way, labs can grow their capabilities without growing their staff, helping them stay competitive. Beyond that, many of the best reasons to use automation are harder to fit into a traditional accounting framework, like a safer working environment and increased experimental reproducibility.

Several studies support the cost-effectiveness of laboratory automation:

- An economic analysis of a hospital that implemented TLA for diagnostic testing found that break-even from reduced staffing costs was expected in less than five years, while four out of four key performance indicators accrued benefits.

- A study of four microbiology labs that switched to TLA found annual labor savings between $268,000 and $1,200,000, while productivity increased 18-93%.

Challenges and Considerations in Implementing Lab Automation

While the benefits of laboratory automation are considerable, implementing automation presents its challenges. Each piece of a lab automation solution is a large investment, and proper planning is necessary to ensure a successful transition. That means working with and training staff to update workflows, as well as addressing all of the technical needs of automation technology.

Staff need to be trained to use the new equipment efficiently, accounting for the learning curve. Technical support must be available to make any last-minute adjustments or deal with unexpected issues, should they arise. When installing automation into lab spaces that weren’t designed with automation in mind, it’s important to anticipate possible increased demands on space, heat management, and electricity.

Because there are so many options for automation, including a wide range of devices offered by many suppliers, a key element for successful implementation is ensuring that each piece of the process works well with the others. Without careful planning, it’s possible to discover too late that a type of liquid medium is incompatible with new equipment, said microbiologist Carey-Ann Burnham for Clinical Chemistry.

Moreover, devices from different suppliers may not follow the same design principles, or they may use incompatible software. Device-agnostic laboratory orchestration software like Biosero’s Green Button Go, and custom device drivers can help bridge these gaps.

Real-World Applications of Laboratory Automation

Automation has reduced costs and enhanced outcomes for labs of all kinds. Here are a few examples of real-world laboratory automation benefits, all enabled by Biosero’s Green Button Go software:

- By creating pipelines that support diagnostic technicians as they test patient samples, human error in sample processing and data entry is minimized, while the proportion of patients who receive accurate results from the first test is maximized.

- An analytical chemistry lab’s new processing pipeline yielded an automation advantage in sample preparation of 94% time savings.

- Through clever custom solutions and error-responsive systems, drug discovery labs were able to automate the entire liquid chromatography/mass spectrometry workflow.

Future of Laboratory Automation

Laboratory automation technology advances quickly, and there are many reasons to stay abreast of developments in the field. Robotic solutions progress year-after-year, and it is increasingly possible to automate complex, multi-step processes.

Advances on the software side are making lab automation solutions into smarter, more adaptable tools for scientists. Process mining involves a pipeline where data is collected directly from work processes as they are performed, which is then analyzed and used to inform improvements to the process. Incorporating process mining into automation allows systems to adapt to the specific context of a particular laboratory, systematically identifying and addressing inefficiencies.

Smart and targeted implementations of artificial intelligence are being incorporated into automation in a variety of ways. For example, advanced liquid handling systems can monitor fluid pressure within samples and alert a scientist if an anomaly occurs.

Even labs currently using automation need to stay up to date in order to keep enjoying the benefits of laboratory automation. Regular upgrades to automation systems are the best way to make use of the latest methodological advancements and data formats while ensuring continuous technical support from suppliers.

Why Your Lab Should Consider Automation

It’s harder and harder to stay competitive in research while relying entirely on manual processes because the benefits of laboratory automation are felt across the entire research operation.

- Automation improves productivity and operational consistency so that reliable results arrive faster, without the need to expand the staff.

- Automating sample processing, labeling, and data entry reduces the rate of human errors, increasing confidence and reducing waste.

- With automated systems tracking each step of the research pipeline, documentation and compliance become much easier, and workflows can be made more efficient.

- Allowing robots to handle hazardous or repetitive tasks makes labs safer places to work.

- By improving productivity while reducing costs, automated solutions can provide incredible returns on investment.

Implementing automation does not have to be complicated or intimidating. Many solutions today, like Biosero’s Green Button Go software, can be easily integrated into existing lab infrastructure. Contact us to learn more.

FAQS

What are the primary benefits of laboratory automation?

Laboratory automation can increase productivity while decreasing costs. With robots and software support, lab processes can be streamlined, and repetitive tasks can be executed quickly, precisely, and reliably. Automation can circumvent the need to hire many additional staff while decreasing waste associated with inefficient processes.

How does automation improve research quality?

Automated solutions can improve experimental reproducibility and data integrity. Even the best scientists make mistakes when preparing experiments manually, but robots can perform repetitive processes like liquid handling with incredible precision and consistency. Implementing automation in sample processing, analysis, and sample and data storage minimizes the introduction of human errors in other parts of the research process.

Is laboratory automation suitable for small labs?

Absolutely, laboratory automation can be highly beneficial for small labs, and it covers a wide spectrum. Automation can range from small steps, where specific tasks are automated while scientists manually manage the samples, to full-scale systems with robotics that minimize hands-on tasks. For smaller labs, automating even just the most time-consuming or repetitive steps can make a big impact. With solutions like Biosero’s Green Button Go, labs can integrate workflows across different devices, allowing scientists to schedule and monitor processes automatically, no matter the level of automation needed.