Lab orchestration is a buzzy topic these days and the term is being used frequently to talk about connecting the disparate equipment in a lab. But orchestration for us goes beyond the basics of physically connecting a few instruments in a workcell.

Lab orchestration is the ability to connect automated and manual tasks in a coordinated flow of digital and physical materials. With this type of connectivity, you unlock the ability to gather analytics on total lab performance and connect via API to all the other software suites available in the lab. The goal is to give humans a portal to conduct all the complex activity taking place around research and help drive its productivity forward.

Over the last year, we’ve worked with a range of labs to reach these orchestration goals and we’ve seen a few blueprints that neatly summarize how different labs adapt orchestration to fit their needs. These blueprints provide a vision for how an orchestrated lab might come together. And while each lab is different, the basic blueprints provide inspiration. Biosero’s Chief Commercial Officer, Ryan Bernhardt, and we’ve broken them down here for you.

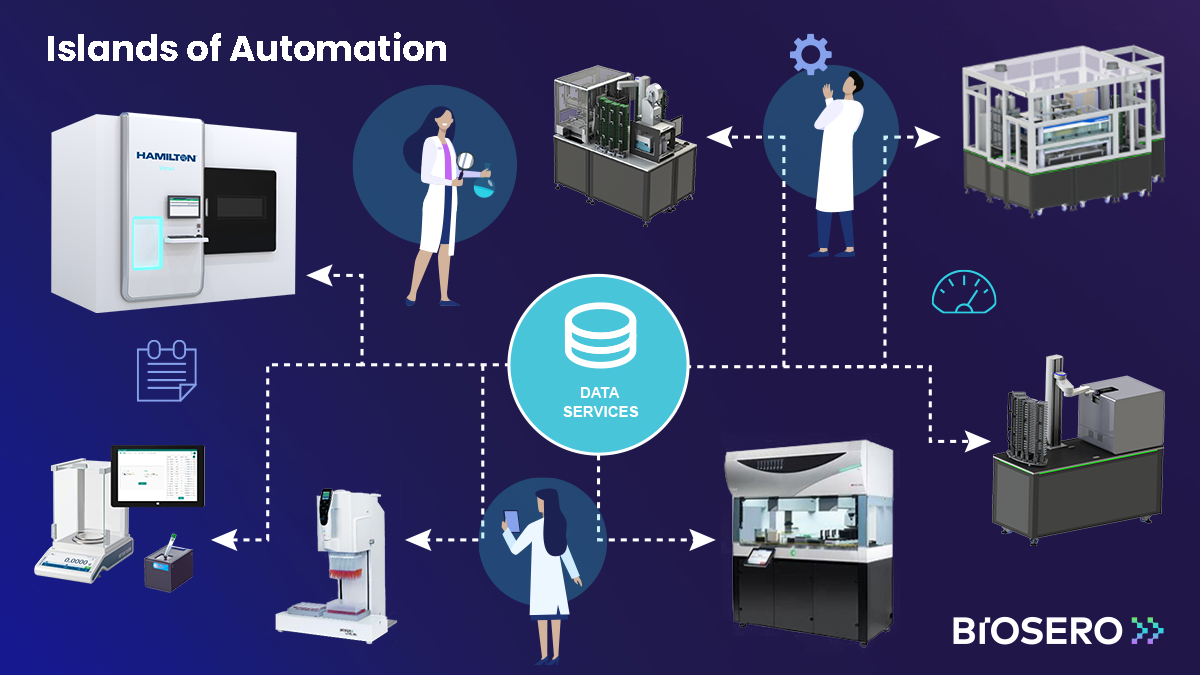

Lab Orchestration Blueprint #1: Islands of automation

Scientists who choose this option have distinct automation stations in the lab with data services at the center of their ecosystem. With this setup, they manually transport samples, labware, and other consumables between each station. It is a great option for scientists who don’t have a lot of samples to work with or who may be automating their lab for the first time.

This first blueprint allows the ability to digitally connect these disparate islands so they are harmonized. While this opens the door for digital connectivity, islands of automation still have the constraint of physical connectivity through manual transportation, so these labs are still relying on operators within the lab who physically take lab consumables from one island to another.

There may be delays in moving samples from one instrument to the next if an experiment ends after normal working hours, and there is a greater risk of human error in the process.

Advantages:

- A great way to start harmonizing disparate instruments and workstations

- Complete data capture and workflow tracking

- Creates the framework for even more digital connectivity down the road

- Reduces the interaction between operators and instrumentation

Considerations:

- Still relies on manual efforts for physical connectivity around the lab

- Creates a “hurry up and wait” mentality

- Productivity may not extend beyond traditional working hours

- Data collected may still be disparate

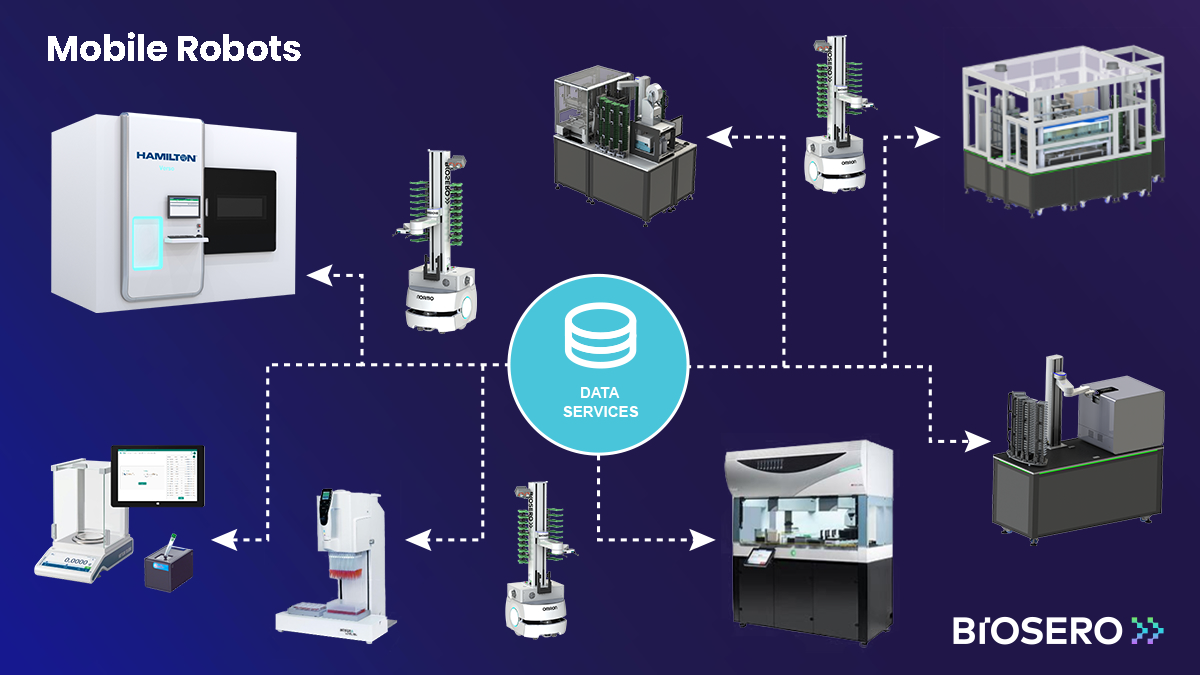

Lab Orchestration Blueprint #2: Mobile robots

For labs where it’s important to limit scientists’ manual labor moving samples or consumables from point A to point B, mobile robots are a great addition. While humans manage the overall system, robots interact with the instruments and workstations, moving samples and labware around the lab. Mobile robots can safely move samples between workstations in the same space, or even on different floors or in different buildings. They can also extend the capabilities of their labs with self-assembling workstations; mobile robots transport equipment needed to assemble new workstations on demand and later disassemble the components of the custom workstation and move the pieces to the next job.

Mobile robots are also helpful because they can keep systems running after traditional work hours. We can set things up so scientists run experiments during the day and then assign robots to keep working through the night.

Mobile robots are a great option for labs that need more flexibility and productivity. Also, by delegating more responsibility to machines, labs can lower the risks of costly mistakes.

Advantages:

- Complete data capture and tracking

- Eliminates human error and variability

- Flexible sample transportation across labs and even beyond the lab

- Operates harmoniously with lab staff

- Extends capabilities of workstations with on-demand assembly

- Dynamic ability means it stays flexible with any lab layout changes made

- No spatial constraints of fixed assets in the lab

- Allows for increased productivity beyond working hours

Considerations:

- Can only interact with one area of the lab at a time

- Low speed across workstations

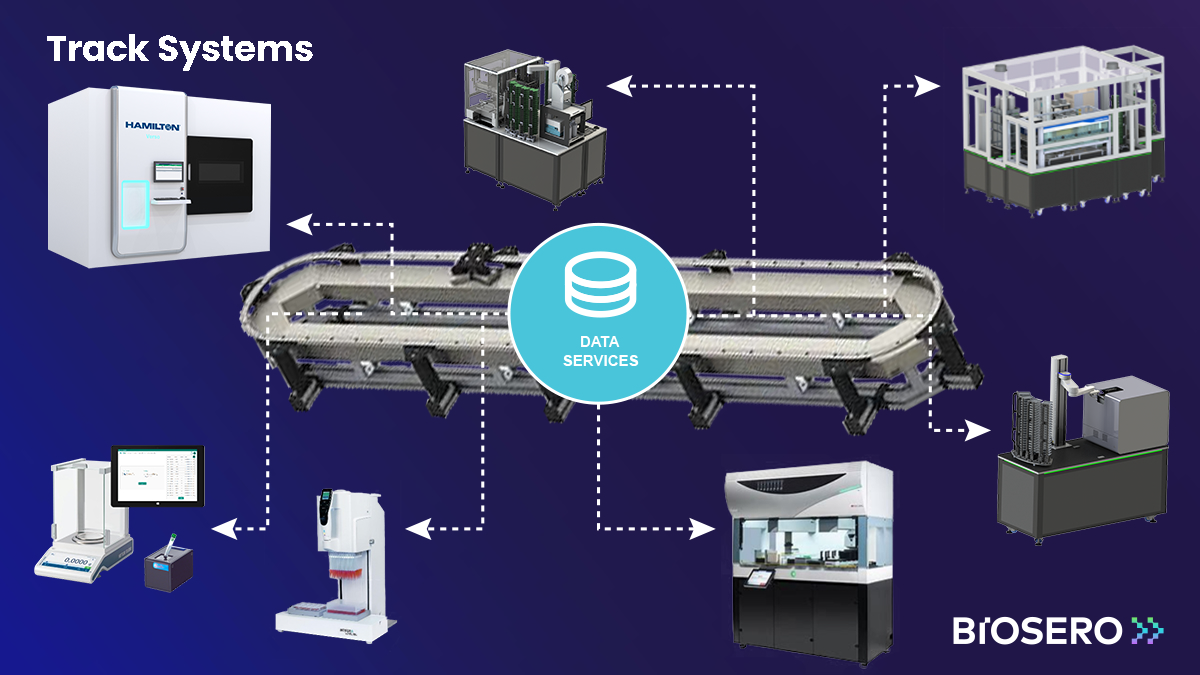

Lab Orchestration Blueprint #3: Track systems

This setup also delegates transportation activities to machines, but these machines are larger and more likely built into the lab setup. Options include magnetic track-based systems and conveyor belts that connect multiple workstations in the lab and transport samples and other consumables between them. Like mobile robots, track systems reduce the risks of mistakes and limit scientists’ interactions with instruments and workstations. But unlike mobile robots which only interact with a single system at a time, track systems can safely distribute items across multiple workstations simultaneously.

Advantages:

- Complete data capture and tracking

- Hardware agnostic

- Allows for the ability to stitch together an end-to-end workflow based on your needs

- Visual capabilities to view entire process, samples, vehicles, etc. via digital twin monitoring

- Eliminates human error and variability

- Simultaneous delivery of materials to different workstations

- Faster transportation across workstations

Considerations:

- Spatial constraints within the lab need to be considered

- Less dynamic if layout of lab changes

All of these blueprints are part of the lab automation continuum, from the beginnings of digitization to a fully automated workflow. It’s worth noting, however, that even in the most advanced automated labs, there are still going to be manual tasks that require a human touch, like preparing the solutions and reagents, or triaging a problematic sample. But there’s no reason that data on these touchpoints can’t be captured and delivered into the same analytics systems that capture the automated work There will always be the vital need for scientists to be ingrained in the process for a successful lab experience. Lab orchestration is about freeing scientists from manual and repetitive tasks, while also helping capture and unify all of the workflow data automatically.

What’s in common across all these blueprints

Here’s what they all have in common: each utilizes our Green Button Go Data Services application to digitally connect all the systems in the lab. GBG Data Services gathers and harmonizes information from all of the instruments, workstations, and systems in the lab and stores it in a centralized data warehouse. It captures sample data and experimental results as well as details about the protocols and procedures such as incubator temperature, experiment start and end times, and so on.

The digital connectivity provided by GBG Data Services is extremely powerful. Scientists can view the combined information from all of their systems with full context about their workflows. Based on what they learn from this data, they can adjust workflows, switch up experimental plans, and identify cases of instrument failure or quality issues.

Where the setups differ is in the physical interactions between the systems and instruments in the lab.

Get Biosero’s help launching orchestration for your lab today! If you want help implementing automation in your lab, let’s connect.

Want to automate smarter, not harder? Join the Biosero newsletter and stay in the loop with the latest lab automation strategies, success stories, and product updates.