Automating ELISA preparation

ELISA preparation

Automating ELISA preparation

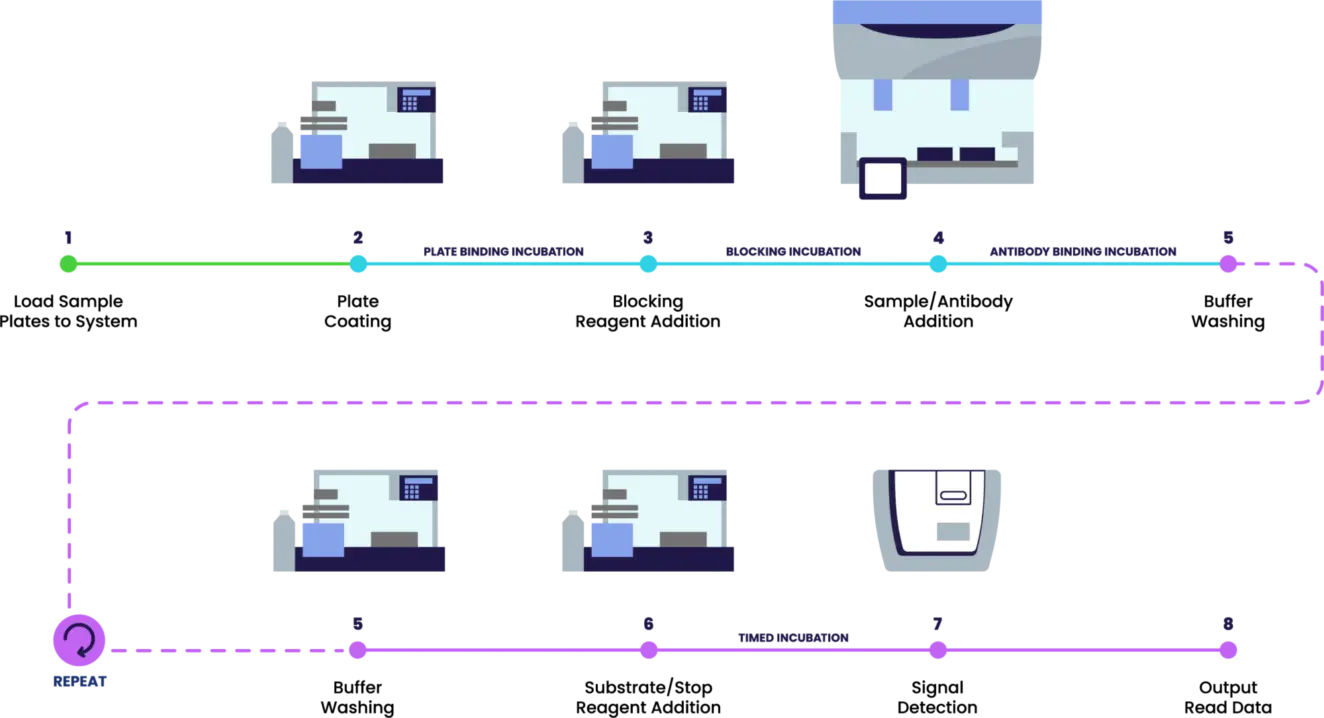

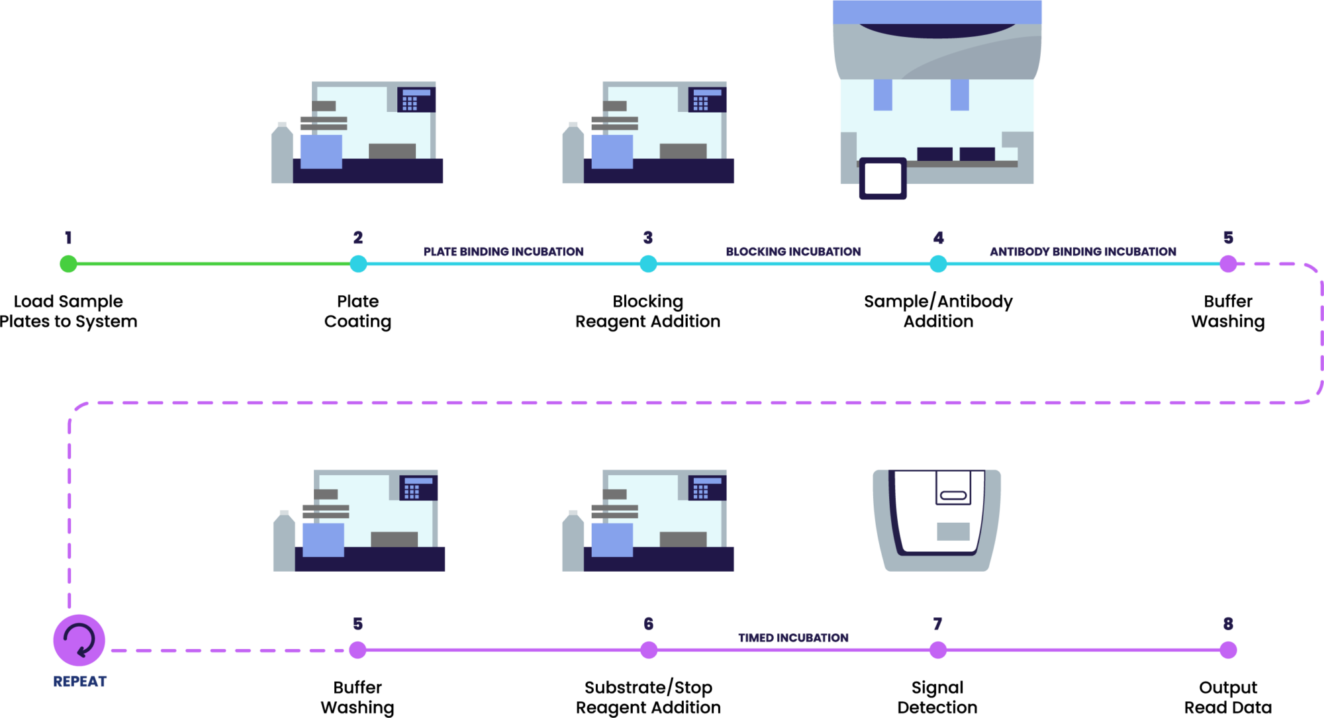

Automating ELISA preparation streamlines laboratory workflows by ensuring consistent results through precise liquid handling and standardized protocols. It increases efficiency by reducing hands-on time, allowing scientists to focus on higher-value tasks while the system runs independently.

Automation enhances robustness by minimizing human error and variability, leading to more reliable data. Additionally, it eliminates the need for overnight shifts, improving work-life balance and reducing operational costs. This approach accelerates throughput while maintaining high-quality outcomes, making it an invaluable tool for modern laboratories.

3 reasons to automate ELISA preparation

Accuracy

Automation ensures precise pipetting and standardized procedures, reducing variability and human error for more reliable results

Efficiency

Automated systems handle repetitive tasks, freeing up time for researchers to focus on data analysis or other high priority work

Cost and time savings

Eliminating the need for manual labor during extended hours, such as overnight shifts, reduces operational costs and speeds up workflows

Example ELISA preparation workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your ELISA Preparation workflow.

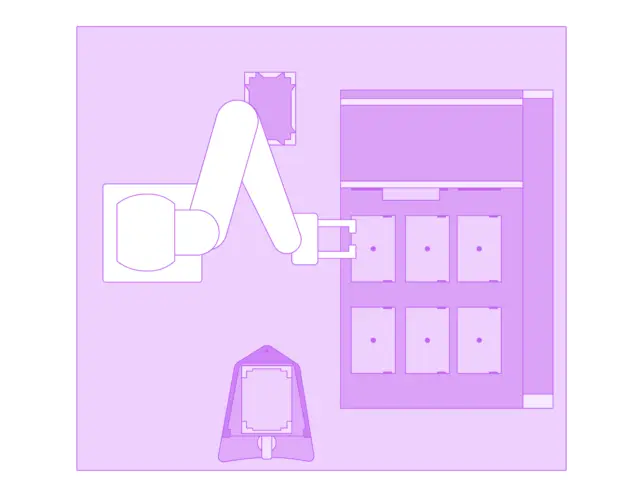

Small workcell

Small workcell

A small workcell for ELISA Preparation is ideal for labs seeking an efficient solution with a compact footprint. It accommodates lower throughput needs while maintaining consistent and reliable results. Its cost-effectiveness makes it accessible for smaller teams or budgets, and its modular design often allows for easy expansion as demands grow. This setup provides a flexible and scalable option for laboratories prioritizing space, affordability, and adaptability.

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

1x Liquid Handler (Agilent Bravo)

1x Heater Shaker (Inheco Thermoshake)

1x Random Access Plate Storage Hotel

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

1x Liquid Handler (Agilent Bravo)

1x Heater Shaker (Inheco Thermoshake)

1x Random Access Plate Storage Hotel

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

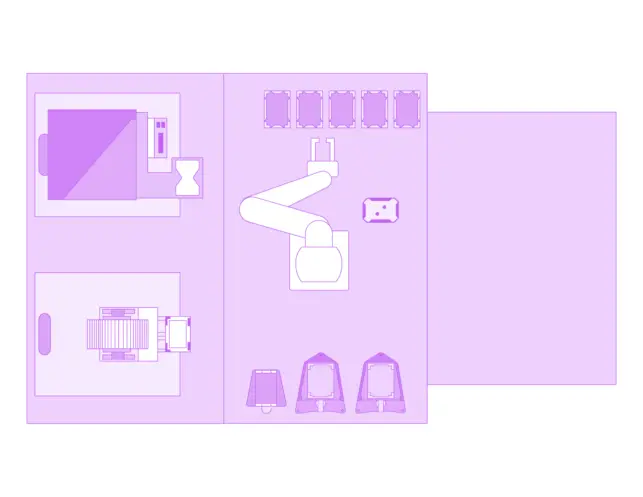

Medium workcell

Medium workcell

A medium-sized workcell for ELISA Preparation offers a balance of capacity and efficiency, catering to labs with moderate to high throughput needs. With a slightly larger footprint, it supports more extensive workflows while maintaining precision and reliability. Though it involves higher initial costs, the increased throughput and automation deliver significant time savings and operational efficiency. This option is ideal for laboratories looking to scale their productivity without committing to full-scale industrial systems.

Feature details for Hardware

Hardware:

1x Robotic Arm (PAA KX2)

1x Liquid Handler (Tecan Fluent 480)

1x Multimode Plate Reader (Agilent-BioTek Synergy Neo2)

1x Plate Washer (Agilent-BioTek EL405)

1x Plate Desealer (Azenta XPeel)

1x Plate Sealer (Agilent PlateLoc)

6x Heater Shaker (Inheco Thermoshake)

2x Random Access Plate Storage Hotel

1x Last In First Out Plate Stacker

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm (PAA KX2)

1x Liquid Handler (Tecan Fluent 480)

1x Multimode Plate Reader (Agilent-BioTek Synergy Neo2)

1x Plate Washer (Agilent-BioTek EL405)

1x Plate Desealer (Azenta XPeel)

1x Plate Sealer (Agilent PlateLoc)

6x Heater Shaker (Inheco Thermoshake)

2x Random Access Plate Storage Hotel

1x Last In First Out Plate Stacker

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

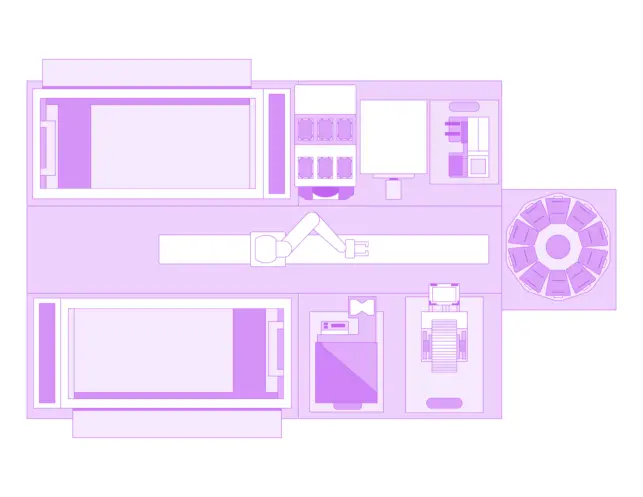

Large workcell

Large workcell

A large workcell for ELISA Preparation is designed for laboratories with the highest throughput demands, offering unparalleled efficiency and scalability. While it requires a substantial footprint, it supports large-scale workflows, minimizing manual intervention and maximizing productivity. The higher upfront cost is offset by its capacity to handle complex operations with speed and precision. Additionally, its design often includes room for further expansion, making it a future-proof solution for growing labs or facilities focused on industrial-scale processes.

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

2x Liquid Handler (Hamilton STARlet)

1x Microplate Centrifiuge (BioNex HiG4)

1x Microplate Incubator (LiCONiC STX44)

1x Multimode Plate Reader (Biotek Synergy Neo2)

1x Tube Rack Capper/Decapper (Hamilton LabElite)

1x Automated Plate Storage Carousel (PAA CS-10)

4x Plate Washer (Biotek EL405)

6x Heater Shaker (Inheco Thermoshake)

1x Plate Desealer (Azenta XPeel)

1x Plate Sealer (Agilent PlateLoc)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

2x Liquid Handler (Hamilton STARlet)

1x Microplate Centrifiuge (BioNex HiG4)

1x Microplate Incubator (LiCONiC STX44)

1x Multimode Plate Reader (Biotek Synergy Neo2)

1x Tube Rack Capper/Decapper (Hamilton LabElite)

1x Automated Plate Storage Carousel (PAA CS-10)

4x Plate Washer (Biotek EL405)

6x Heater Shaker (Inheco Thermoshake)

1x Plate Desealer (Azenta XPeel)

1x Plate Sealer (Agilent PlateLoc)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Best use cases for bringing in automation

Automation is a good fit for laboratories with regularly scheduled workflows, ensuring consistency and timely results.

Regular schedule

It excels in environments with high throughput needs, handling large sample volumes efficiently.

Hands-free automation

Labs where staff are responsible for tasks away from the bench benefit from automation by freeing up time for more critical activities.

Continuous operation

It is also ideal for facilities currently requiring off-hour staffing on weekends or holidays, as automated systems can operate 24/7, far beyond the capacity of a technician, reducing labor demands while maintaining productivity.

What to watch out for

Manual review and release of samples processed by the system may still be necessary, requiring oversight to maintain data integrity.

The increased data volume generated by automated workflows demands robust LIMS or ELN infrastructure to manage and store information effectively.

Higher throughput often leads to increased consumption of labware and tips, necessitating efficient waste management solutions to handle the larger volume.