Automating protein characterization

Protein characterization

Automating protein characterization

Automating protein characterization has clear advantages. It ensures consistent results, reduces manual steps, and increases lab efficiency. Teams can extend run times without adding staff—overnight or across shifts—freeing up resources and improving data reliability. For labs working under time pressure or strict quality requirements, automation adds robustness and scalability to a critical process.

3 reasons to automate protein characterization

Streamlined workflows

Automation integrates different stages of the protein characterization process, making it easier to manage and analyze complex experiments

Increased accuracy and reproducibility

Automated systems minimize human error, ensuring consistent and reliable results across multiple runs

High-throughput analysis

Automation facilitates the analysis of large numbers of proteins, which is crucial for high-throughput research areas like proteomics and drug discovery

Example protein characterization workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your Protein Characterization workflow.

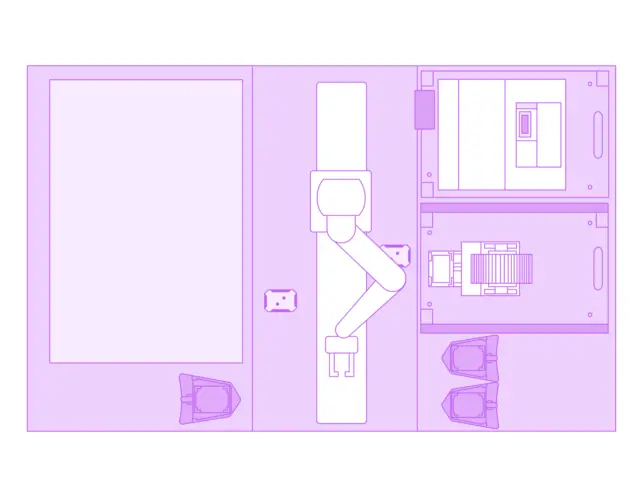

Small workcell

Small workcell

A small automated workcell for protein characterization offers an ideal entry point into lab automation with a compact footprint, lower throughput, and cost-effective deployment. Designed for core tasks like automated pipetting and mixing, assay setup for protein concentration or activity, plate transfers between instruments, and data collection from a plate reader, it streamlines workflows while maintaining flexibility. Optional features such as sample tracking and basic error logging further enhance reliability. As needs evolve, the system is modular and scalable, allowing users to expand capacity or integrate additional instruments—making it a smart investment that grows with your lab.

Feature details for Hardware

Hardware:

1x Robotic Arm on Rail (Brooks PreciseFlex robot PF400)

1x Barcode reader on Arm

1x Liquid Handling System (Tecan Fluent)

1x Plate Reader (BMG LABTECH CLARIOstar)

1x Microplate Centrifuge (BioNex HiG)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

3x Plate Hotels

2x Regrip Nest

Feature details for Software

Integration Software:

GBG Scheduler

Feature details for Hardware

Hardware:

1x Robotic Arm on Rail (Brooks PreciseFlex robot PF400)

1x Barcode reader on Arm

1x Liquid Handling System (Tecan Fluent)

1x Plate Reader (BMG LABTECH CLARIOstar)

1x Microplate Centrifuge (BioNex HiG)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

3x Plate Hotels

2x Regrip Nest

Feature details for Software

Integration Software:

GBG Scheduler

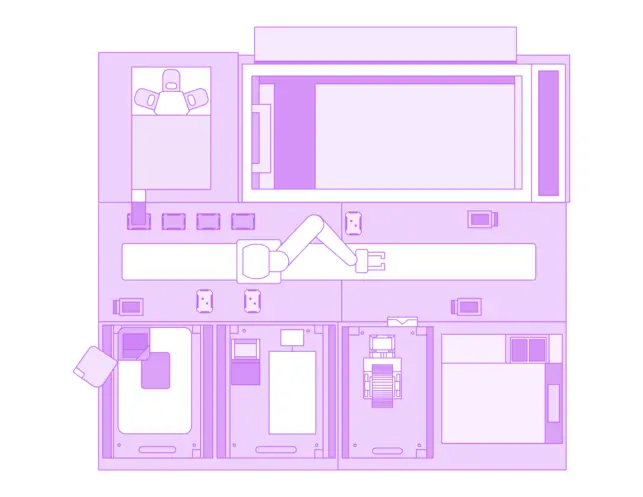

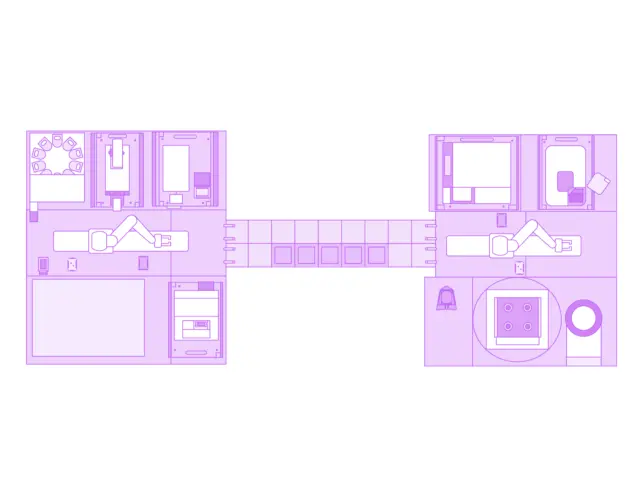

Medium workcell

Medium workcell

A mid-sized protein characterization workcell offers the ideal balance between automation power and lab flexibility. With a larger footprint and higher throughput capacity, it supports more complex workflows—including sample prep, assay setup, and integrated analysis—while maintaining a manageable scale. The system accommodates a wider range of instruments and plate formats, making it well-suited for labs looking to boost efficiency and reproducibility. And with its modular, upgrade-ready design, it provides a clear path to expand capabilities as scientific needs evolve.

Feature details for Hardware

Hardware:

1x Robotic Arm on Rail (Brooks PreciseFlex robot PF400)

1x Barcode reader on Arm

1x Liquid Handling Platform (Hamilton Company STAR)

1x Microplate Centrifuge (BioNex HiG)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

4x Heater-cooler shaker (QINSTRUMENTS BioShake Q1)

2x Automated Tube Decapper Capper (Azenta IntelliXCap 96 & 48)

2x Thermo Cycler (Inheco ODTC)

1x High-throughput Capillary Electrophoresis System (SCIEX BioPhase 8800)

1x CE-SDS and icIEF Instrument (ProteinSimple Maurice)

1x Labware Carousel (LiCONiC LPX100)

1x Multimode Plate Reader (Agilent-BioTek Synergy HTX)

3x Lid Hotel 5 Pos.

4x Regrip Nest

Feature details for Software

Integration Software:

GBG Scheduler

Feature details for Hardware

Hardware:

1x Robotic Arm on Rail (Brooks PreciseFlex robot PF400)

1x Barcode reader on Arm

1x Liquid Handling Platform (Hamilton Company STAR)

1x Microplate Centrifuge (BioNex HiG)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

4x Heater-cooler shaker (QINSTRUMENTS BioShake Q1)

2x Automated Tube Decapper Capper (Azenta IntelliXCap 96 & 48)

2x Thermo Cycler (Inheco ODTC)

1x High-throughput Capillary Electrophoresis System (SCIEX BioPhase 8800)

1x CE-SDS and icIEF Instrument (ProteinSimple Maurice)

1x Labware Carousel (LiCONiC LPX100)

1x Multimode Plate Reader (Agilent-BioTek Synergy HTX)

3x Lid Hotel 5 Pos.

4x Regrip Nest

Feature details for Software

Integration Software:

GBG Scheduler

Large workcell

Large workcell

For labs managing complex or large-scale protein characterization workflows, larger integrated systems provide a powerful advantage. Larger integrated systems offer a substantial increase in throughput and automation, ideal for high-volume protein characterization workflows. While they require a larger footprint and higher upfront investment, they deliver significant efficiency gains with advanced software integration and minimal hands-on time. These systems are designed to grow with your needs—modular and expandable to support evolving assay complexity and scale. Perfect for labs seeking reproducibility, speed, and long-term flexibility. Ideal for high-demand environments, these systems support faster decision-making, reduce manual error, and future-proof your lab for growing complexity and volume.

Feature details for Hardware

Hardware:

2x Robotic Arm on a Rail (Brooks PreciseFlex PF400)

2x Barcode reader on Arm

1x On-Arm Hook to open Agilent Multisampler drawer

1x Liquid Handling System (Tecan Fluent)

1x Microplate Centrifuge (BioNex HiG)

1x Labware Carousel (LiCONiC LPX220)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Azenta Life Sciences a4S)

2x Automated Tube Decapper Capper (Azenta IntelliXCap 96 & 48)

2x Thermo Cycler (Inheco ODTC)

1x Multimode Plate Reader (BMG CLARIOstar)

1x Magnetic levitation transportation system (B&R ACOPOS 6D)

2x LC-MS System (Agilent 1290 Infinity II LC System with Q-ToF)

1x High-throughput Capillary Electrophoresis System (SCIEX BioPhase 8800)

1x CE-SDS and icIEF Instrument (ProteinSimple Maurice)

1x Hotel 21 MTP Pos. (PAA Universal access hotel HR21U)

2x Lid Hotel

2X PlateOrient (HighRes BioSolutions Plate Orient)

2x Regrip Nest

Feature details for Software

Integration Software:

2x Green Button Go Scheduler

1x Green Button Go Orchestrator

Feature details for Hardware

Hardware:

2x Robotic Arm on a Rail (Brooks PreciseFlex PF400)

2x Barcode reader on Arm

1x On-Arm Hook to open Agilent Multisampler drawer

1x Liquid Handling System (Tecan Fluent)

1x Microplate Centrifuge (BioNex HiG)

1x Labware Carousel (LiCONiC LPX220)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Azenta Life Sciences a4S)

2x Automated Tube Decapper Capper (Azenta IntelliXCap 96 & 48)

2x Thermo Cycler (Inheco ODTC)

1x Multimode Plate Reader (BMG CLARIOstar)

1x Magnetic levitation transportation system (B&R ACOPOS 6D)

2x LC-MS System (Agilent 1290 Infinity II LC System with Q-ToF)

1x High-throughput Capillary Electrophoresis System (SCIEX BioPhase 8800)

1x CE-SDS and icIEF Instrument (ProteinSimple Maurice)

1x Hotel 21 MTP Pos. (PAA Universal access hotel HR21U)

2x Lid Hotel

2X PlateOrient (HighRes BioSolutions Plate Orient)

2x Regrip Nest

Feature details for Software

Integration Software:

2x Green Button Go Scheduler

1x Green Button Go Orchestrator

Best use cases for bringing in automation

For high-throughput demands

Automation delivers large volumes of samples for consistent, repeatable processing

For routine or scheduled assays

Automation delivers when you need it, running daily or weekly, and improving standardization along the way

For extending hours of operations

Automation is a powerful solution for extending operational hours, enabling unattended runs overnight, on weekends, or during holidays

For data-rich environments

Automation simplifies the acquisition and integration of results across multiple instruments, helping labs scale efficiently while ensuring reproducibility and data integrity

What to watch out for

LIMS/ELN integration

Systems must be capable of handling high data volumes and linking metadata across instruments.

Instrument compatibility

Not all analytical devices are automation-ready without modification

Scalability & flexibility

Rigid systems may not accommodate evolving assay formats or new instruments

Training & workflow design

Automation requires rethinking protocols for hands-free operation and user retraining