Automating flow cytometry preparation and analysis

Flow cytometry

Automating flow cytometry preparation and analysis

Flow cytometry is a powerful tool for analyzing cell populations with speed and precision. It provides critical insights in research and production, from immunology and cancer studies to biopharmaceutical manufacturing.

Where automation makes a difference

Higher throughput

Automated systems can process large numbers of samples in less time. Optimizes resource use by integrating sample handling, acquisition, and analysis

Improved data quality & reproducibility

Automation minimizes human error and variability in sample processing. It also ensures standardized, consistent, and reliable results across experiments and batches

Scalability & flexibility

Adapts to increasing sample volumes without compromising quality. Supports automated workflows for different applications, from research to manufacturing

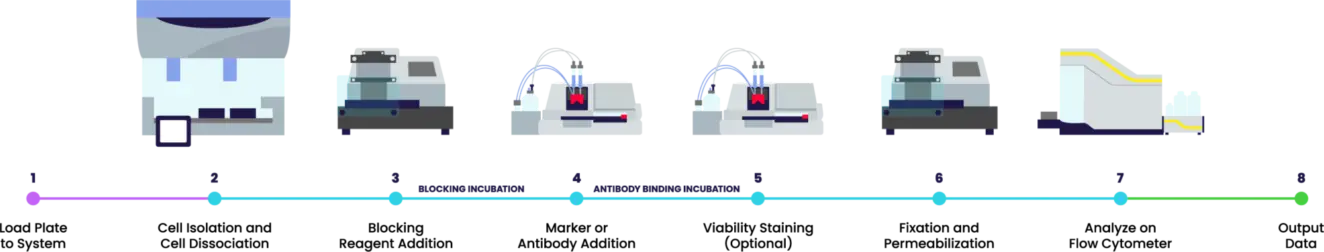

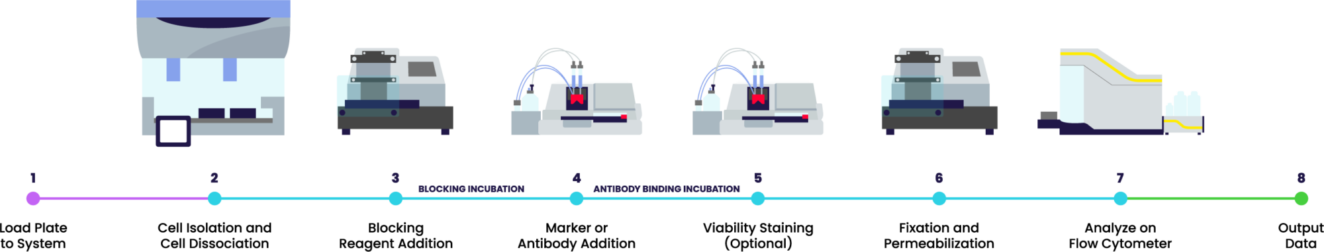

Example flow cytometry preparation and analysis workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your Flow Cytometry Preparation and Analysis workflow.

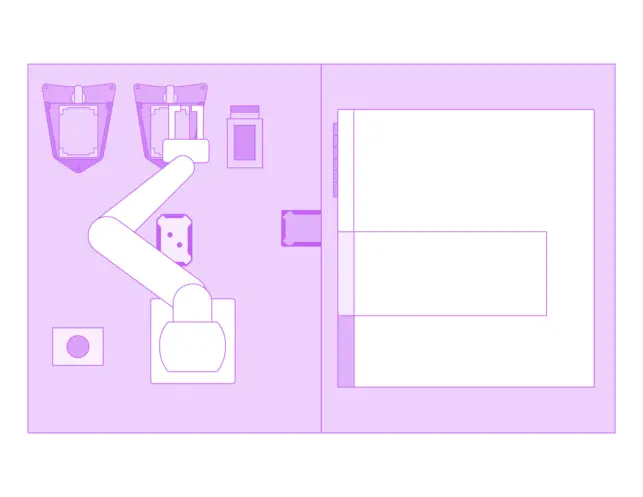

Small workcell

Small workcell

A compact robotic workcell automates plate loading efficiently, ideal for labs with limited space and lower throughput requirements. It picks up, scans, and processes plates accurately with minimal manual intervention, saving time and reducing errors. The small footprint and affordable setup costs make it a practical solution, especially for facilities starting automation. As your needs grow, the system can easily expand to handle increased workloads, offering flexibility to scale operations smoothly.

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

1x On-Robot Arm Barcode Reader

1x Flow Cytometer (BioRad ZE5)

1x automated Storage (Thermo Fisher Cytomat 2-LIN)

2x Random access Plate Storage Hotels

1x Plate Storage (5 position Hotel)

1x Biosero Regrip Nest

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

1x On-Robot Arm Barcode Reader

1x Flow Cytometer (BioRad ZE5)

1x automated Storage (Thermo Fisher Cytomat 2-LIN)

2x Random access Plate Storage Hotels

1x Plate Storage (5 position Hotel)

1x Biosero Regrip Nest

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

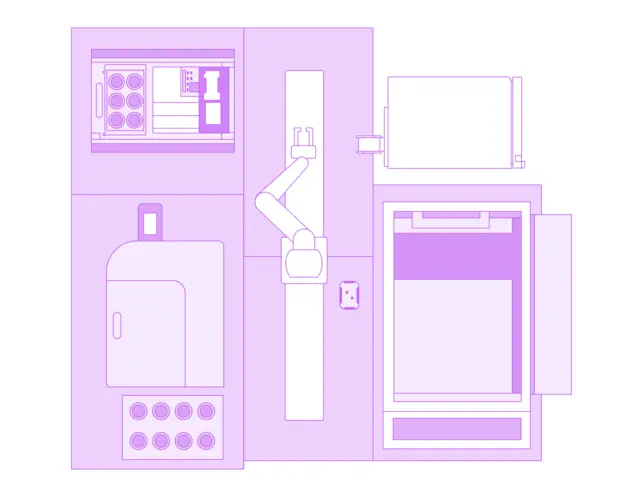

Medium workcell

Medium workcell

A slightly larger workcell offers increased throughput and greater flexibility, making it ideal for growing operations. Its larger footprint lets you handle bigger products or higher volumes efficiently. While it comes at a modestly higher cost, the investment pays off through scalable performance and easy expansion, adapting seamlessly as your business evolves.

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

1x Liquid Handler (Hamilton STARlet)

1x Microplate Centrifuge (BioNex HiG4)

1x Plate Washer (Agilent-BioTek EL405)

1x Microplate Incubator (LiCONiC STX110)

1x Flow Cytometer (Sartorius iQue)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

1x Liquid Handler (Hamilton STARlet)

1x Microplate Centrifuge (BioNex HiG4)

1x Plate Washer (Agilent-BioTek EL405)

1x Microplate Incubator (LiCONiC STX110)

1x Flow Cytometer (Sartorius iQue)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

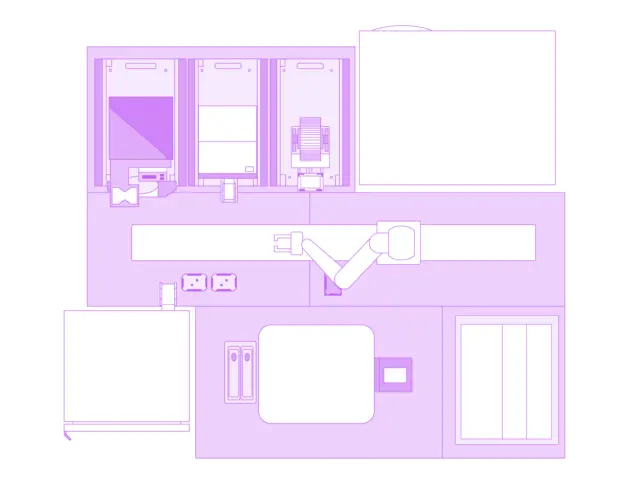

Large workcell

Large workcell

A larger system is designed for labs that need more capacity and faster processing. It can handle a much higher throughput, which means more data, or more processes at the same time. Costs are higher—hardware, software, and maintenance—but you get a system that doesn’t hit limits so quickly. It will likely need additional software to manage and monitor everything. That adds complexity but also more control.

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

1x Liquid Handler (Tecan Fluent)

1x Echo acoustic Liquid Handler (Beckman Coulter Echo 500 model)

1x Flow Cytometer (BD FACSLyric)

1x Microplate Centrifuge (BioNex HiG4)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

1x Plate Washer (Blue Cat Bio Bluewasher)

1x Reagent Dispenser (Thermo Fisher Multidrop Combi nl)

2x Delidder Device (HighRes Biosolutions LidValet)

1x Microplate Incubator (LiCONiC STX220)

1x Microplate Orienter (HighRes Biossolutions PlateOrient)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Feature details for Hardware

Hardware:

1x Robotic Arm on a Rail (Precise PF400)

1x Liquid Handler (Tecan Fluent)

1x Echo acoustic Liquid Handler (Beckman Coulter Echo 500 model)

1x Flow Cytometer (BD FACSLyric)

1x Microplate Centrifuge (BioNex HiG4)

1x Plate Seal Remover (Azenta Life Sciences XPeel)

1x Plate Sealer (Agilent PlateLoc)

1x Plate Washer (Blue Cat Bio Bluewasher)

1x Reagent Dispenser (Thermo Fisher Multidrop Combi nl)

2x Delidder Device (HighRes Biosolutions LidValet)

1x Microplate Incubator (LiCONiC STX220)

1x Microplate Orienter (HighRes Biossolutions PlateOrient)

Feature details for Software

Integration Software:

Green Button Go Scheduler with necessary Device Drivers

Best use cases for bringing in automation

Automation is a good fit for laboratories with regularly scheduled workflows, ensuring consistency and timely results

Clinical and diagnostic applications

Standardized workflows improve reproducibility in clinical diagnostics, immunomonitoring, and biomarker discovery

Automation ensures controlled incubation times, antibody order, and data comparability over multiple runs

Minimal sample volume & cost reduction

Small volume assays (e.g., 20 µL in 384-well plates) use less reagent compared to manual methods (100 µL per tube)

Lower antibody consumption reduces costs, especially for expensive fluorophores

No-wash or fixation-free assays

Automation works well with no-wash protocols to minimize cell loss and streamline workflows

Essential for delicate cell types like stem cells, primary immune cells, or bone marrow samples

Reducing Human Error & Operator Fatigue

When running multiple plates or working with complex sample handling steps, automation prevents inconsistencies

Particularly useful for long workflows involving multiple antibody titrations, time-sensitive steps, or high-precision pipetting

What to watch out for

Scalable data management

Automated sample preparation generates high-throughput data, demanding efficient handling, storage, and analysis pipelines

Instrument compatibility

Not all flow cytometers support direct automation, requiring careful selection of compatible systems and integration strategies

Workflow integration

Custom protocol development and validation are often necessary to ensure seamless integration with existing sample preparation workflows

Initial investment & validation

Automation in flow cytometry preparation requires upfront investment, along with time for optimizing protocols and troubleshooting before routine implementation