Automating analytical chemistry

Analytical chemistry

Automating analytical chemistry

Custom methods for identifying, characterizing, and quantifying formulations are subject to change. Leverage Biosero's hardware-agnostic automation approach to accelerate current workflows without sacrificing the data generated.

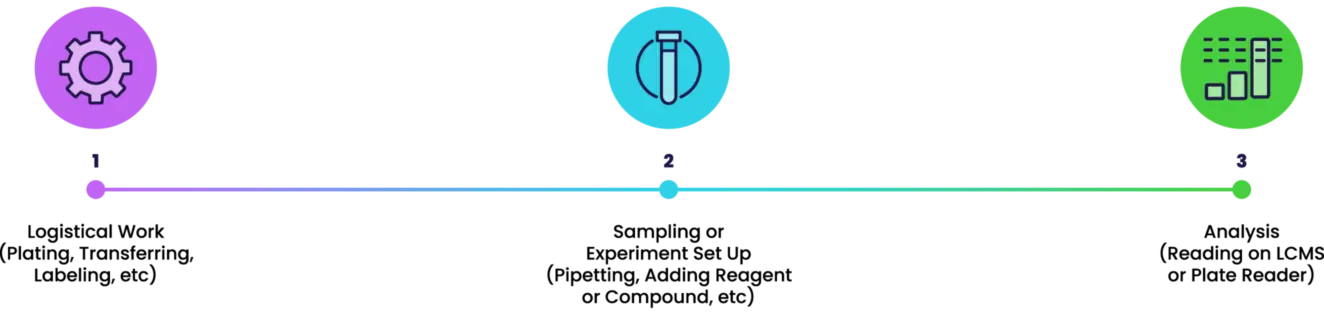

3 reasons to automate analytical chemistry

Automating custom sample preparation

Reducing errors from manual sample prep and freeing up valuable time for scientists

Simplify complex compound analysis

Instead of running one experiment at a time, chain analyses together to extract rich data at the push of a button

Manage time-intensive experiments with automated scheduling

Dynamically schedule recurring assays at pre-determined times for increased analytical throughput and data transfer

Example analytical chemistry workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your Analytical Chemistry workflow.

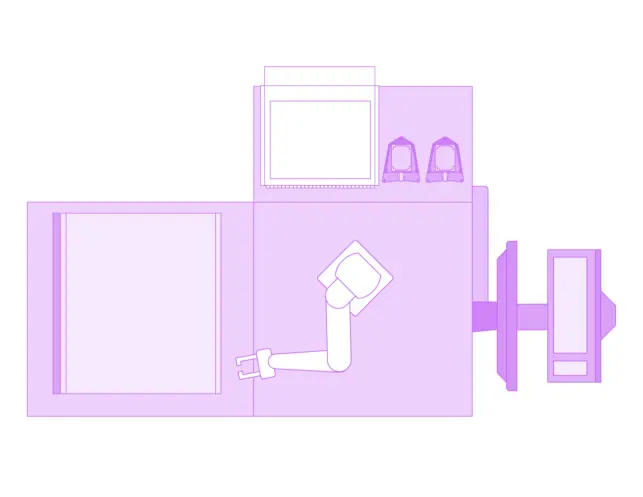

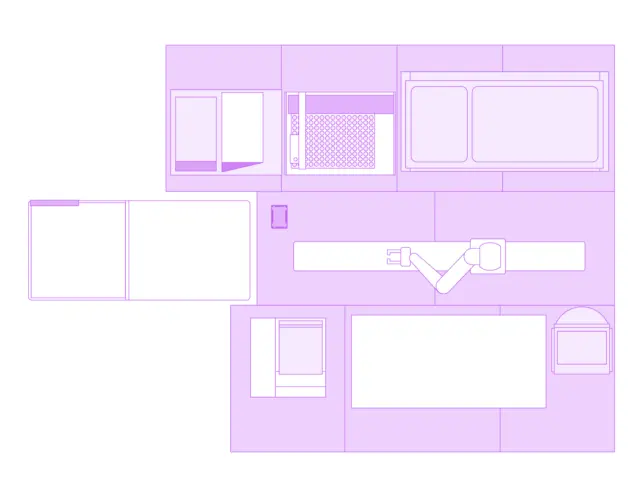

Small workcell

Small workcell

This workcell automates key steps in analytical chemistry to ensure precise sample preparation and consistent reagent handling for high-quality data. This setup enhances reproducibility, reduces turnaround time, and supports walkaway operation for demanding workflows.

Feature details for Hardware

Hardware:

Agilent LCMS

Lynx700 Liquid Handler

UR5 Robotic Arm

2x Plate Hotels

Feature details for Software

Integration Software:

Green Button Go Scheduler

Feature details for Hardware

Hardware:

Agilent LCMS

Lynx700 Liquid Handler

UR5 Robotic Arm

2x Plate Hotels

Feature details for Software

Integration Software:

Green Button Go Scheduler

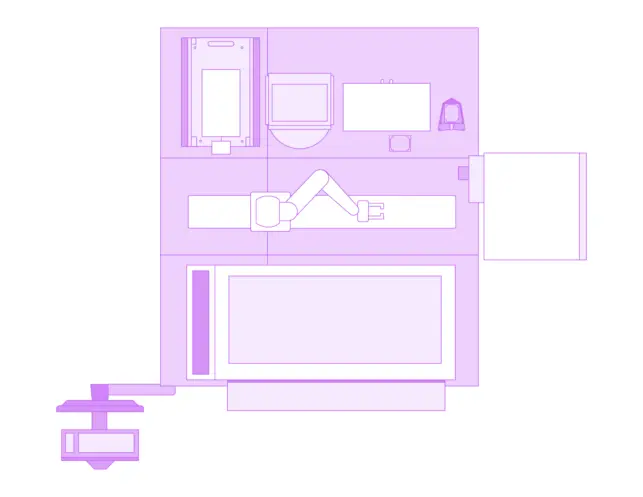

Medium workcell

Medium workcell

This workcell supports high-throughput analytical workflows. Samples are automatically prepared, tracked, and processed through tightly controlled conditions to ensure consistent assay setup and data integrity. The combination of incubation, spectrophotometry, and chromatography enables multi-dimensional analysis with minimal user interaction. This system maximizes walkaway time, improves traceability, and delivers robust, reproducible results for complex analytical applications.

Feature details for Hardware

Hardware:

PF400 on 1.5M Rail

Hamilton STAR

LiCONiC STX500

Scinomix VXL

Azenta FluidX IntelliXcap

BMG SpectroSTAR

1x Plate Hotels

Feature details for Software

Integration Software:

Green Button Go Scheduler

Feature details for Hardware

Hardware:

PF400 on 1.5M Rail

Hamilton STAR

LiCONiC STX500

Scinomix VXL

Azenta FluidX IntelliXcap

BMG SpectroSTAR

1x Plate Hotels

Feature details for Software

Integration Software:

Green Button Go Scheduler

Large workcell

Large workcell

This fully integrated system enables seamless, unattended preparation of analytical-ready samples from long-term storage through final analysis. It delivers high-throughput, reproducible processing with complete traceability across complex chemistry workflows. The workcell is divided into two zones—Storage and Tube Analysis, and Sample Preparation—connected by a central honeycomb module for automated transfer of plates and tube racks.

Feature details for Hardware

Hardware:

C5 on 2M Rail Robotic Arm

Beckman Coulter Biomek i7

Genevac EZ-2 Evaporator

Thermo Fisher Cytomat Skyline

Sirius Omnitasker

Waters UPLC

Waters Autopurification System

Hamilton Storage Verso Q75

Feature details for Software

Integration Software:

Green Button Go Scheduler

Feature details for Hardware

Hardware:

C5 on 2M Rail Robotic Arm

Beckman Coulter Biomek i7

Genevac EZ-2 Evaporator

Thermo Fisher Cytomat Skyline

Sirius Omnitasker

Waters UPLC

Waters Autopurification System

Hamilton Storage Verso Q75

Feature details for Software

Integration Software:

Green Button Go Scheduler

Best use cases for bringing in automation

Labs with regularly scheduled workflows

High-throughput demands

Staff is tasked with many responsibilities beyond the bench or off-hour staffing is leveraged

What to watch out for

Labs may encounter delays due to manual review or release of samples coming off the system, especially if human verification is still required

The lab's LIMS or ELN infrastructure must be capable of handling the increased data volume generated by automated runs

Waste management should be considered, as automation typically results in higher consumption of labware and tips, which must be accounted for in both cost and disposal logistics