Automating NGS prep

NGS

Automating NGS prep

Automating next-generation sequencing (NGS) workflows brings immediate benefits to the lab by increasing consistency, improving reproducibility, and significantly extending walk-away time. This leads to a more robust and scalable workflow that supports high-throughput sequencing demands while freeing up staff to focus on analysis and experiment design rather than repetitive sample prep tasks.

3 reasons to automate NGS prep

Eliminate variability from NGS prep

Control every step of the process—from bead mixing to thermal cycling

Maximize throughput and walkaway time

Coordinate all devices and allow for unattended operation

Ensure complete sample traceability

Integrate with LIMS, enabling bi-directional communication and results reporting

Typical NGS prep workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your NGS prep workflow.

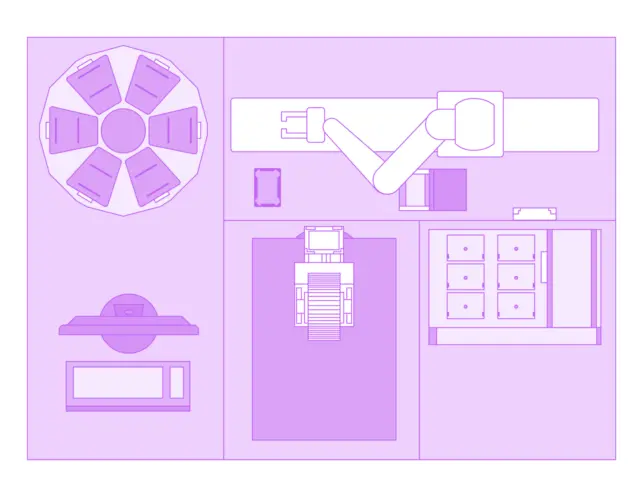

Small workcell

Small workcell

This workcell automates the full NGS preparation workflow, moving plates between devices with a robotic arm for walkaway operation. This integrated system minimizes manual intervention, improves consistency across batches, and allows users to focus on analysis instead of pipetting.

Feature details for Hardware

Hardware:

PF400 on 1M Rail

Agilent PlateLoc

Azenta XPeel

Inheco ODTC

QINSTRUMENTS BioShake

BioTek Synergy HTX Reader

Agilent Bravo

KingFisher Presto

BioNex HiG3 Centrifuge

PAA 6 Position Carousel

Feature details for Software

Integration Software:

Green Button Go

Feature details for Hardware

Hardware:

PF400 on 1M Rail

Agilent PlateLoc

Azenta XPeel

Inheco ODTC

QINSTRUMENTS BioShake

BioTek Synergy HTX Reader

Agilent Bravo

KingFisher Presto

BioNex HiG3 Centrifuge

PAA 6 Position Carousel

Feature details for Software

Integration Software:

Green Button Go

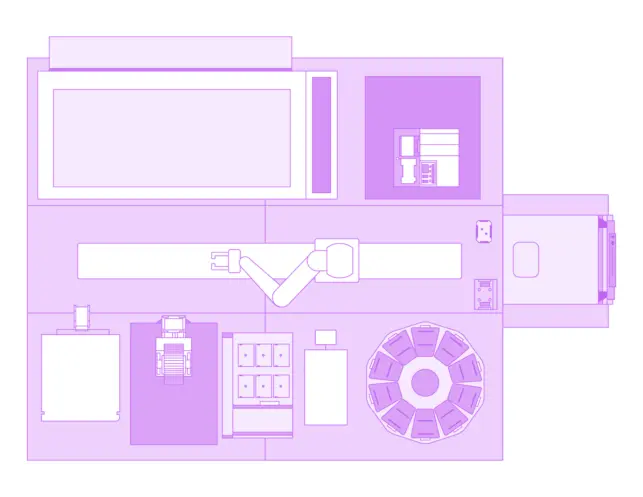

Medium workcell

Medium workcell

This high-throughput NGS prep workcell is designed to streamline complex workflows by running multiple processes in parallel. Green Button Go dynamically schedules and coordinates each operation in real time, ensuring that devices are utilized efficiently and that the system responds to timing dependencies or resource availability. By orchestrating this network of specialized instruments, the system minimizes idle time, reduces user burden, and delivers high-quality, consistent libraries—ready for sequencing with confidence.

Feature details for Hardware

Hardware:

PF400 on 2M Rail

Hamilton STAR

Agilent Bravo

PAA 10 Position Carousel

2 TRobot96 Thermal Cyclers

2 KingFisher Prestos

Azenta IntelliXCap 96

Hettich Rotanta 460 Centrifuge

BioTek EL405 Plate Washer

LiCONiC STX44 Incubator

Agilent PlateLoc

Azenta XPeel

Feature details for Software

Integration Software:

Green Button Go

Feature details for Hardware

Hardware:

PF400 on 2M Rail

Hamilton STAR

Agilent Bravo

PAA 10 Position Carousel

2 TRobot96 Thermal Cyclers

2 KingFisher Prestos

Azenta IntelliXCap 96

Hettich Rotanta 460 Centrifuge

BioTek EL405 Plate Washer

LiCONiC STX44 Incubator

Agilent PlateLoc

Azenta XPeel

Feature details for Software

Integration Software:

Green Button Go

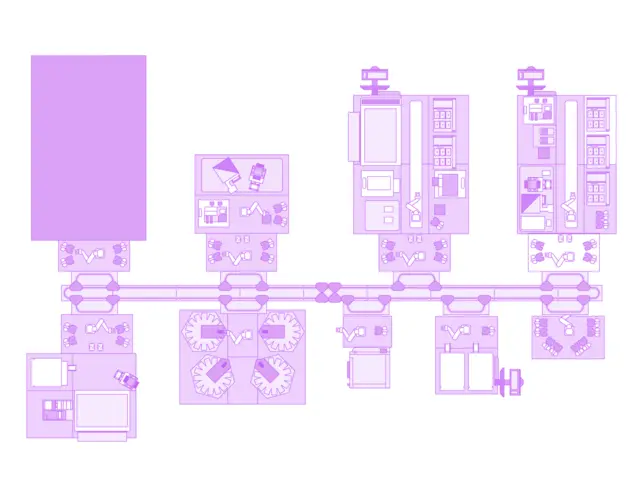

Large workcell

Large workcell

This integrated, track-based automation system supports massively high-throughput genomics workflows by connecting multiple specialized workcells into one cohesive, intelligently scheduled operation. Each workcell is dedicated to a specific phase of the sequencing pipeline, and Green Button Go Orchestrator coordinates movement, timing, and resource allocation across the entire track to ensure uninterrupted, walkaway processing. This architecture delivers end-to-end, future-ready automation for genomics, blending orchestration, traceability, and data intelligence in one unified platform.

Feature details for Hardware

Hardware:

13x Robotic Arm (PAA KX2)

7x Liquid Handlers (5x Agilent Bravo, 2x Hamilton STARlet)

4x Plate Washers (Agilent-BioTek EL405)

2x Extraction Instruments (ThermoFisher KingFisher Flex)

2x Plate Imagers (Agilent-BioTek Synergy HTX)

3x Centrifuge (Bionex HiG3)

1x Chilled Centrifuge (Hettich Rotanta 460)

4x Thermal Cyclers (Inheco ODTC)

3x Plate Peelers (Azenta XPeel)

3x Plate Sealers (Agilent PlateLoc)

3x Capper/Decapper (2x Azenta IntelliXCap 96, 1x Hamilton LabElite ID Capper)

4x Plate Shakers (QINSTRUMENTS Q1)

3x Incubators (LiCONiC STX110 BT)

1x Chilled Tube Storage (Hamilton Storage Verso Q20)

4x High Density Labware Storage (HighRes Biosolutions MicroServe)

33x Plate Storage Hotels

1x Track-Based Transportation System (Rockwell Automation Magnemotion Lite)

Feature details for Software

Integration Software:

9x Green Button Go Scheduler

Green Button Go Orchestrator

Feature details for Hardware

Hardware:

13x Robotic Arm (PAA KX2)

7x Liquid Handlers (5x Agilent Bravo, 2x Hamilton STARlet)

4x Plate Washers (Agilent-BioTek EL405)

2x Extraction Instruments (ThermoFisher KingFisher Flex)

2x Plate Imagers (Agilent-BioTek Synergy HTX)

3x Centrifuge (Bionex HiG3)

1x Chilled Centrifuge (Hettich Rotanta 460)

4x Thermal Cyclers (Inheco ODTC)

3x Plate Peelers (Azenta XPeel)

3x Plate Sealers (Agilent PlateLoc)

3x Capper/Decapper (2x Azenta IntelliXCap 96, 1x Hamilton LabElite ID Capper)

4x Plate Shakers (QINSTRUMENTS Q1)

3x Incubators (LiCONiC STX110 BT)

1x Chilled Tube Storage (Hamilton Storage Verso Q20)

4x High Density Labware Storage (HighRes Biosolutions MicroServe)

33x Plate Storage Hotels

1x Track-Based Transportation System (Rockwell Automation Magnemotion Lite)

Feature details for Software

Integration Software:

9x Green Button Go Scheduler

Green Button Go Orchestrator

Best use cases for bringing in automation

When uniformity is critical

Automation delivers workflow consistency and sample traceability by reducing manual touchpoints

When working over night or on weekends is a regular requirement

Automation unlocks walkaway time for staff so that runs can continue every single hour of the week

High-throughput sequencing and regulated environments

Automation delivers robust, scalable, and audit-ready processes

What to watch out for

Sample tracking and release steps may still require manual review if not integrated with a LIMS

Informatics infrastructure must manage the volume of metadata and intermediate QC points generated by automated prep

Increased usage of labware and tips can require operational changes

Complex library prep protocols may need to be adapted for automation compatability