Automating cell maintenance

Cell maintenance

Automating cell maintenance

If you’re looking for ways to improve the consistency of your cell feeding and maintenance cycles, automation can deliver the robust and reliable outcomes you need at any scale.

3 reasons to automate cell maintenance

Less human variability

Automating plate handling and liquid transfers reduces the risk of human error and contamination

Low timing variance

More cells can be fed and maintained on a consistent schedule

Higher throughput

Automating a multi-day or week assay allows you to keep track of more batches/plates at a time

Typical cell maintenance workcells

No matter your goals or throughput needs, we can design and implement a solution to automate your workflow.

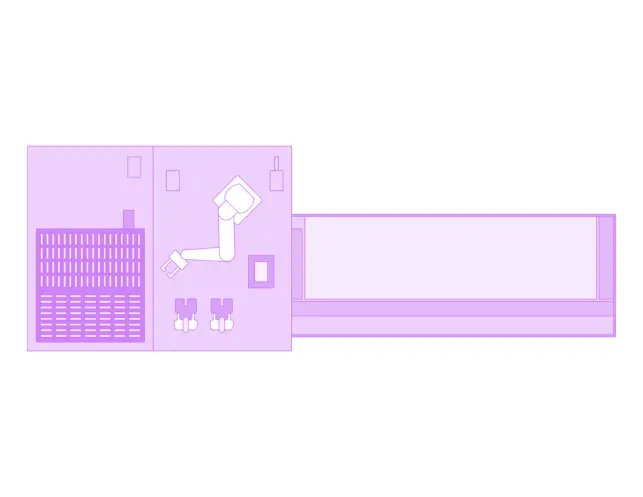

Small workcell

Small workcell

A small Cell Maintenance workcell can take some of the strain off of your personnel by automating a portion or all of your cell maintenance workload, while maintaining a small footprint. The workcell is designed to automate the feeding and surveillance of cells via the integration of imaging and liquid handling capabilities. This can also be expanded to include other portions of your workflow such as inoculation and various endpoint tests.

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

2x Plate Hotel (Biosero)

1x Imaging Cytometer (Nexcelom Celigo)

1x Liquid Handler (Tecan Fluent 1080)

1x Incubator (Thermo Fisher Cytomat 10)

1x Tube Capper/Decapper (Azenta IntelliXCap)

1x Tube 2D Barcode Scanner (Ziath DataPaq Cube)

Feature details for Software

Integration Software:

Green Button Go Scheduler

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

2x Plate Hotel (Biosero)

1x Imaging Cytometer (Nexcelom Celigo)

1x Liquid Handler (Tecan Fluent 1080)

1x Incubator (Thermo Fisher Cytomat 10)

1x Tube Capper/Decapper (Azenta IntelliXCap)

1x Tube 2D Barcode Scanner (Ziath DataPaq Cube)

Feature details for Software

Integration Software:

Green Button Go Scheduler

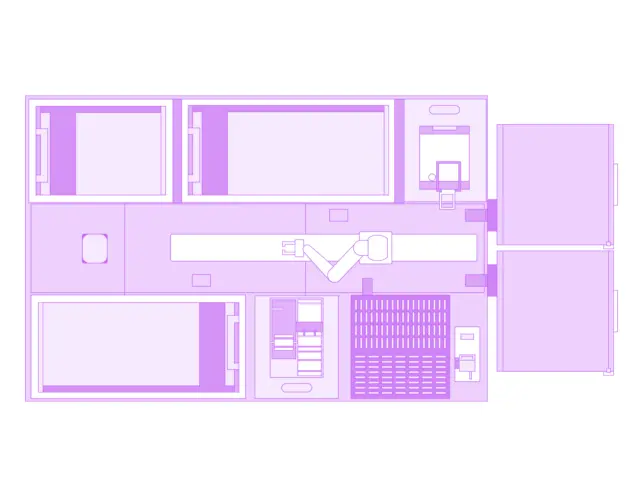

Medium workcell

Medium workcell

Depending on your volume and throughput, a medium Cell Maintenance workcell can take on the bulk of the cell maintenance workload. With some additional functionality compared to the smaller Cell Maintenance workcell, the medium workcell can assist in providing higher throughput and end-to-end operation.

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

2x Plate Imager (Agilent-BioTek Cytation 5)

3x Liquid Handler (2x Hamilton STAR/ 1x Hamilton STARlet)

4x Incubator (2x Thermo Fisher Cytomat 24, 2x Thermo Fisher Cytomat 10)

2x Tube Capper/Decapper (Hamilton LabElite)

1x Centrifuge (Hettich Rotanta)

Feature details for Software

Integration Software:

Green Button Go Scheduler

Feature details for Hardware

Hardware:

1x Robotic Arm (Precise PF400)

2x Plate Imager (Agilent-BioTek Cytation 5)

3x Liquid Handler (2x Hamilton STAR/ 1x Hamilton STARlet)

4x Incubator (2x Thermo Fisher Cytomat 24, 2x Thermo Fisher Cytomat 10)

2x Tube Capper/Decapper (Hamilton LabElite)

1x Centrifuge (Hettich Rotanta)

Feature details for Software

Integration Software:

Green Button Go Scheduler

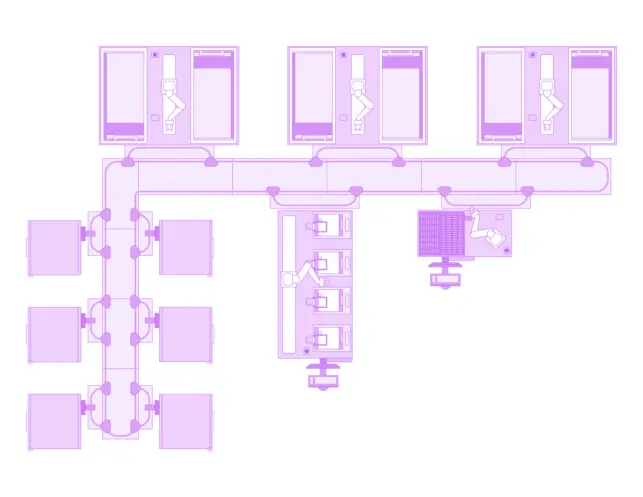

Large workcell

Large workcell

If you are looking to automate a large quantity of samples for a Cell Maintenance protocol, a larger system may provide the tools you are seeking to reach your throughput goals. With significantly more storage, redundancy of equipment, and the inclusion of a buffer station for review, the large Cell Maintenance system can assist in providing increased uptime and throughput over manual processing.

Feature details for Hardware

Hardware:

4x Robotic Arm (Precise PF400)

8x Plate Imager (Agilent-BioTek Cytation 5)

5x Liquid Handler (Hamilton STAR)

2x Plate Washer (Agilent-BioTek EL406)

2x Capper/Decapper (Azenta IntelliXCap 24/48)

1x Chilled Centrifuge (Hettich Rotanta 460)

8x Incubator (6x Thermo Fisher Cytomat 24, 2x Thermo Fisher Cytomat 10)

1x Track-Based Transportation System (Rockwell Automation Magnemotion Lite)

Feature details for Software

Integration Software:

6x Green Button Go Scheduler

Green Button Go Orchestrator Data Services

Green Button Go Orchestrator Workflow Designer

Green Button Go Orchestrator Workflow Conductor

Green Button Go Orchestrator Transportation Manager

Feature details for Hardware

Hardware:

4x Robotic Arm (Precise PF400)

8x Plate Imager (Agilent-BioTek Cytation 5)

5x Liquid Handler (Hamilton STAR)

2x Plate Washer (Agilent-BioTek EL406)

2x Capper/Decapper (Azenta IntelliXCap 24/48)

1x Chilled Centrifuge (Hettich Rotanta 460)

8x Incubator (6x Thermo Fisher Cytomat 24, 2x Thermo Fisher Cytomat 10)

1x Track-Based Transportation System (Rockwell Automation Magnemotion Lite)

Feature details for Software

Integration Software:

6x Green Button Go Scheduler

Green Button Go Orchestrator Data Services

Green Button Go Orchestrator Workflow Designer

Green Button Go Orchestrator Workflow Conductor

Green Button Go Orchestrator Transportation Manager

Best use cases for bringing in automation

Regular schedule

Workflows that are followed on a regular schedule, like regular cell feeding and imaging with a natural endpoint at cell passaging.

Continuous input

Situations where high or continuous throughput is required because of the volume of samples to process.

Multiple tasks

Situations where lab staff are responsible for multiple tasks across a standard workday, and the automation could take on the repetitive, scheduled tasks.

Maintenance schedule

The lab’s cell maintenance schedule requires lab staff to perform tasks during off hours, weekends, or holidays to ensure viability.

What to watch out for

Make sure to have a plan for managing large amounts of waste from used pipetting tips and media removal

In a high throughput automated environment, there will be a larger amount of tip and media waste than you may be expecting from a benchtop environment. Putting special consideration towards the path this waste will take in the design phase will resolve some potential headaches in production.

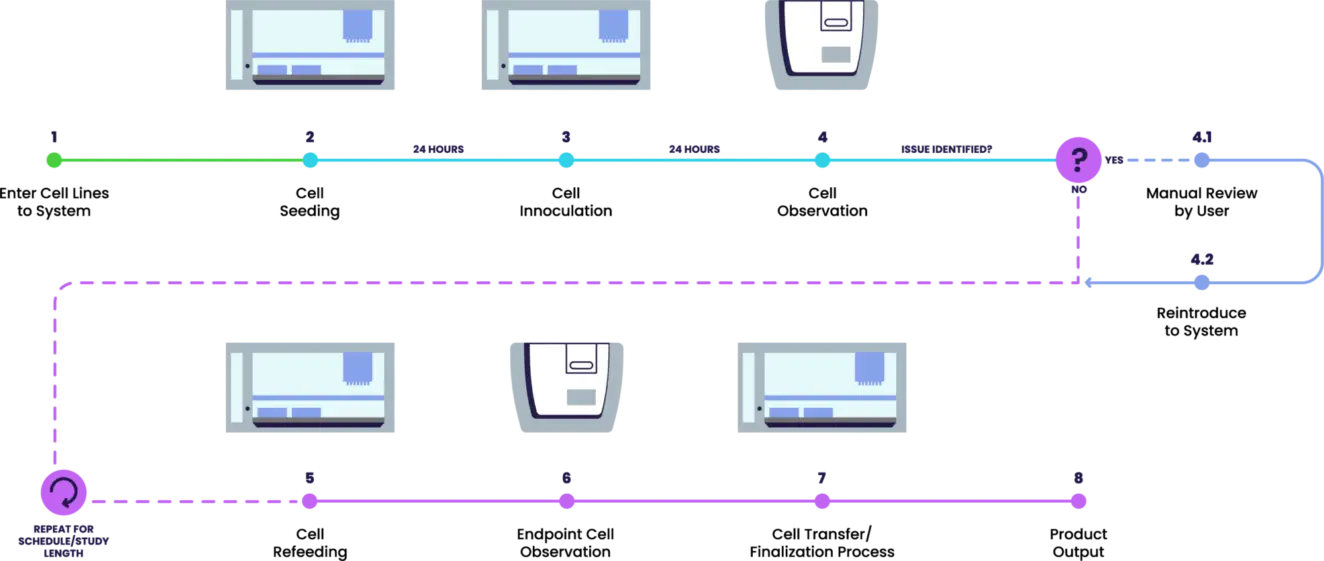

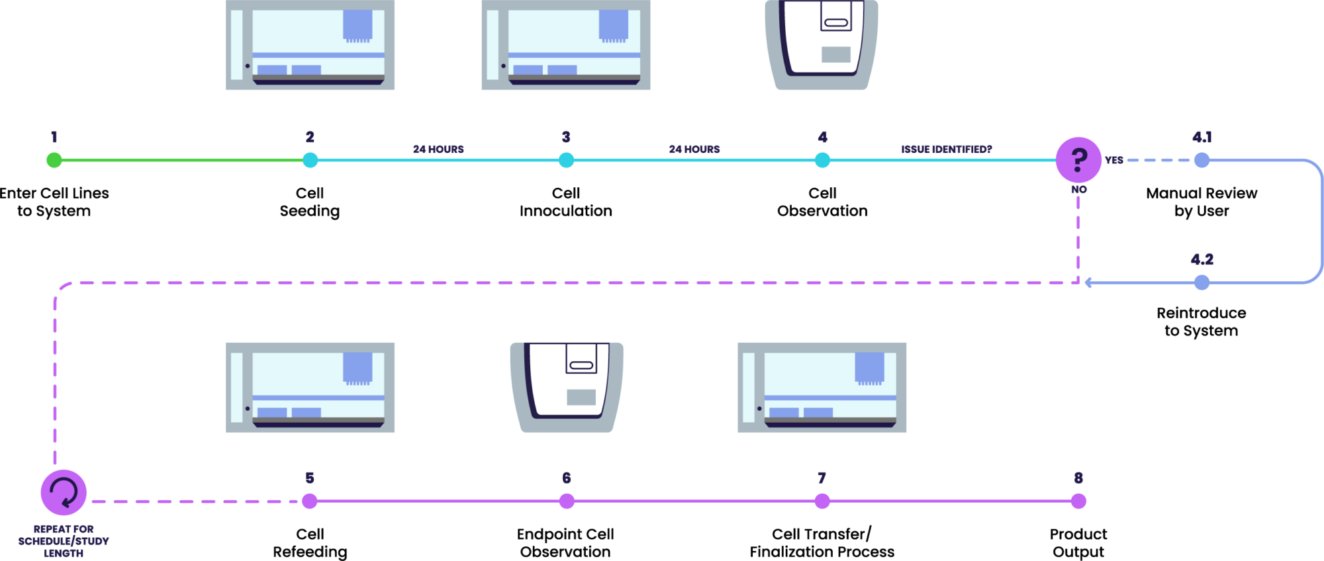

Make sure to have a plan for samples that require manual review or reprocessing

For instance, if you have a particular sample or batch of samples that produce non-standard read results, prepare a process for delineating those particular samples for manual or re-processing.